Philatron 125 SDHA Cable Price Comparison

To download: Right click the link below and select “save link as”

Bronco 125 SDHA Cable Price Comparison.pdf

Introducing..... Bronco125- SDHA™ Flexible Power Cables Small Diameter High Amps (SDHA)

From This

6/4 SO Cable 600 Volts 45 Amps

To This

10/4 SDHA Cable 2,000 Volts 49 Amps

UL Listed / NEC & MSHA Certified

- Better Temperature Range +125°C to -65°C versus SO & SEO Cable +90°C to -40°C

- Better Resistance to Ozone, Oil, and Sunlight than SO & SEO Cable

- Better Handling - Lighter Weight & Smaller Diameter than SO & SEO Cable

- Better Amps (more) than SO & SEO Cables

- Better Voltage (more) than SO & SEO Cables

- Better Price (less)

- Better Quality - 100% Made in the USA versus Offshore Cable

In today’s world of global activities, applications of cables in any climate in the world is

critical to the integrity of your electrical systems. If the cable fails your system fails. The

cables you install to power your systems must be capable of withstanding environmental

abuses of abrasion, heat, cold petroleum chemicals, and harsh handling.

Bronco125™ cables are designed to meet the challenges of your system anywhere in the

world. Bronco125™ cables gives you excellent flexibility and superior operating

temperature ranges from +125°C to -65°C.

Bronco125™ value-to-cost ratio is very high. Bronco125™ cables are intended for users

who requires maximum dependability with minimum replacement and down-time

expenses.

Bronco-125 SDHA Small Diameter High Amps (SDHA)

Conversion Table SO/SEO to SDHA

| TYPE |

SIZE |

NEC

AMPS |

O.D.

INCHES |

TO |

BRONCO |

SIZE |

NEC

AMPS |

O.D.

INCHES |

| SO/SEO |

8/2 |

40 |

0.814 |

TO |

SDHA |

12/2 |

42 |

0.577 |

| SO/SEO |

8/3 |

40 |

0.855 |

TO |

SDHA |

12/3 |

42 |

0.61 |

| SO/SEO |

8/4 |

35 |

0.98 |

TO |

SDHA |

12/4 |

35 |

0.665 |

| SO/SEO |

8/5 |

28 |

1.075 |

TO |

SDHA |

12/5 |

28 |

0.729 |

| SO/SEO |

6/2 |

55 |

0.926 |

TO |

SDHA |

10/2 |

59 |

0.622 |

| SO/SEO |

6/3 |

55 |

0.98 |

TO |

SDHA |

10/3 |

59 |

0.659 |

| SO/SEO |

6/4 |

45 |

1.08 |

TO |

SDHA |

10/4 |

49 |

0.72 |

| SO/SEO |

6/5 |

36 |

1.2 |

TO |

SDHA |

10/5 |

39.2 |

0.791 |

| SO/SEO |

4/2 |

70 |

1.06 |

TO |

SDHA |

8/2 |

74 |

0.794 |

| SO/SEO |

4/3 |

70 |

1.14 |

TO |

SDHA |

8/3 |

74 |

0.903 |

| SO/SEO |

4/4 |

60 |

1.26 |

TO |

SDHA |

8/4 |

65 |

0.977 |

| SO/SEO |

4/5 |

48 |

1.365 |

TO |

SDHA |

8/5 |

52 |

1.03 |

| SO/SEO |

2/2 |

95 |

1.2 |

TO |

SDHA |

6/2 |

99 |

0.878 |

| SO/SEO |

2/3 |

95 |

1.33 |

TO |

SDHA |

6/3 |

99 |

0.929 |

| SO/SEO |

2/4 |

80 |

1.46 |

TO |

SDHA |

6/4 |

87 |

1.08 |

| SO/SEO |

2/5 |

64 |

1.58 |

TO |

SDHA |

6/5 |

69.6 |

1.18 |

| Ampacity based on Ambient Temperature of 86°F (30C°). |

APPLICATION:

For extreme environments and working conditions where maximum resistance to extreme temperatures, chemicals,

oil, fuel, abrasion, and flex fatigue is needed. Designed for powering heavy duty field equipment used in mining,

cranes, construction, drilling rigs, ships, emergency hospital black outs, movie/stage lighting, submersible pump,

undersea and military field operations. Made in the USA to high quality standards.

- Thermoplastic Vulcanizate (TPV) Advanced Synthetic Rubber *

- Extreme Desert to Arctic Temp Ranges: +125°C to -65°C

- Extremely Reliable and Not Effected by Direct Sunlight & Ozone

- Extra Flexibility for Safer Handling

- Chemicals, Oil, Fuel, Salt Water, Abrasion, & Crush Resistant

* Read Bronco-125™ Test Report.

- MSHA Approved - Philatron’s Certification Number: 7K-281151

- Lead and Asbestos Free for Safer Environment

- Extra Flexible Stranded Bare Annealed Copper

- UL Listed Type PPE 2000 Volts 105°C

- UL, CSA, MSHA, & OSHA - for indoors or outdoors use.

Catalog

Number |

AWG

Size |

Number of Conductors |

Bare Cu Stranding |

NEC

*Ampacity |

Nom. O.D.

(Inches) |

Approx. Lbs. M/ft |

|

| SDHA122B |

12 |

2 |

65 X 30 |

42 |

0.577 |

197 |

|

| SDHA123B |

12 |

3 |

65 x 30 |

42 |

0.61 |

249 |

|

| SDHA124B |

12 |

4 |

65 x 30 |

35 |

0.665 |

307 |

|

| SDHA125B |

12 |

5 |

65 X 30 |

28 |

0.729 |

365 |

|

| SDHA102B |

10 |

2 |

104 x 30 |

59 |

0.622 |

240 |

|

| SDHA103B |

10 |

3 |

104 x 30 |

59 |

0.659 |

309 |

|

| SDHA104B |

10 |

4 |

104 X 30 |

49 |

0.72 |

384 |

|

| SDHA105B |

10 |

5 |

104 x 30 |

39.2 |

0.791 |

460 |

|

| SDGA82B |

8 |

2 |

133 x 29 |

74 |

0.794 |

391 |

|

| SDHA83B |

8 |

3 |

133 x 29 |

74 |

0.791 |

571 |

|

| SDHA84B |

8 |

4 |

133 x 29 |

65 |

0.977 |

690 |

|

| SDHA85B |

8 |

5 |

133 x 29 |

52 |

1.03 |

790 |

|

| SDHA62B |

6 |

2 |

259 x 30 |

99 |

0.878 |

490 |

|

| SDHA63B |

6 |

3 |

259 x 30 |

99 |

0.929 |

638 |

|

| SDHA64B |

6 |

4 |

259 X30 |

87 |

1.08 |

875 |

|

| SDHA65B |

6 |

5 |

259 x 30 |

69.6 |

1.18 |

875 |

|

*Ampacity ratings are based on ambient temperature at 87 degrees F (30 degrees C).

COLOR CHART

| # CONDUCTORS |

COLOR |

| 2 |

Black, White |

| 3 |

Black, White, Green |

| 4 |

Black, White, Red, Green |

| 5 |

Black, White, Red, Orange, Green |

Bronco-125 SDHA™

Small Diameter High Amps (SDHA)

Price Comparison Table

SO/SEO to SDHA

June 18, 2012

TYPE

UL Listed |

SIZE |

Price Per Foot |

BRONCO

UL Listed |

SIZE |

Price Per Foot |

SAVINGS |

| SO/SEO |

8/2 |

2.5 |

SDHA |

12/2 |

1.89 |

0.24 |

| SO/SEO |

8/3 |

3.8 |

SDHA |

12/3 |

2.37 |

0.38 |

| SO/SEO |

8/4 |

4.8 |

SDHA |

12/4 |

2.78 |

0.42 |

| SO/SEO |

8/5 |

5.98 |

SDHA |

12/5 |

3.35 |

0.44 |

| SO/SEO |

6/2 |

3.11 |

SDHA |

10/2 |

2.21 |

0.29 |

| SO/SEO |

6/3 |

5.55 |

SDHA |

10/3 |

2.85 |

0.49 |

| SO/SEO |

6/4 |

7.21 |

SDHA |

10/4 |

3.52 |

0.51 |

| SO/SEO |

6/5 |

8.99 |

SDHA |

10/5 |

4.27 |

0.53 |

| SO/SEO |

4/2 |

N/A |

SDHA |

8/2 |

3.62 |

---- |

| SO/SEO |

4/3 |

9.22 |

SDHA |

8/3 |

5.18 |

0.44 |

| SO/SEO |

4/4 |

11.93 |

SDHA |

8/4 |

5.99 |

0.5 |

| SO/SEO |

4/5 |

14.87 |

SDHA |

8/5 |

6.67 |

0.55 |

| SO/SEO |

2/2 |

N/A |

SDHA |

6/2 |

4.42 |

---- |

| SO/SEO |

2/3 |

14.34 |

SDHA |

6/3 |

5.82 |

0.59 |

| SO/SEO |

2/4 |

19.04 |

SDHA |

6/4 |

7.79 |

0.59 |

| SO/SEO |

2/5 |

23.27 |

SDHA |

6/5 |

10.3 |

0.56 |

Note:When comparing prices - compare apples to apples. Insure that cables are UL listed. Only UL listed cables meet the National Electrical Code (NEC) for

prevention of fires and safety.

TO BRONCO 125™ / FROM BRONCO 66

The BRONCO 66 cable line was originally developed in the 1940's, and the

BRONCO 66 trade name came to be synonymous with exceptional quality.

PHILATRON is a direct descent of the individuals who originally developed

BRONCO 66 cables. With over 100 years of expertise in flexible power cables

PHILATRON has embraced the concept of advancing state-of-the-art in wire, cable and a whole series of innovative new

products meeting current and projected market demands in a wide range of industries.

As the technology of wire and cable has been refined over the years, PHILATRON is proud to introduce BRONCO 125™

in a whole new series of cables superior to BRONCO 66 cables.

In today’s world of global activities, applications of cables in any climate of the world is critical to the integrity of your

electrical system. If the cable fails your system fails. The cables you install to power your systems must be capable of

withstanding environmental abuses of abrasion, heat, cold, petroleum, chemicals, and harsh handling.

BRONCO 125™ cables are designed to meet the challenges of your system anywhere in the world. These cables are

extraordinarily tough with superior conductor’s insulation and outer protecting jacket which exhibits the best physical

properties in the industry.

BRONCO 125™ Mining Cables and Portable Power Cables are made of PHILATRON’s exclusive proprietary

thermoplastic vulcanizate (TPV) advanced synthetic rubber, that gives maximum protection from oil and other petroleum

products, corrosive chemicals, ozone, flame, ultraviolet rays, abrasion, cutting, and crushing.

BRONCO 125™ cables gives you excellent flexibility and superior operating temperature ranges from +125°C to -65°C.

BRONCO 125™ value-to-cost ratio is very high. BRONCO 125™ cables are intended for users who requires maximum

dependability with minimum replacement and down-time expenses.

BRONCO 125™ cables are engineered and manufactured to meet the applicable specifications of ASTM (American

Society for Testing Materials), CSA (Canadian Standard Association), ICEA (Insulated Cable Engineers Association),

MIL SPECS (US Military), MSHA (Mine Safety and Health Administration), NEC (National Electric Code), NEMA

(National Electrical Manufacturers Association), OSHA (Occupational Safety and Health Administration), and UL

(Underwriters Laboratories).

BRONCO 125™ cables are now available in the following constructions:

A

Aerial Cables

Aircraft Assembly Plants

Portable Power Cables

Aircraft Generator Cables

Aircraft Ground Support

Equipment

Appliance Machine Wire

Arc Welding Cable

Arctic Special Purpose

Automotive Primary Wire

B

Battery Cable

Boat Cable

Booster Cables

C

Camera Cable

Coiled Cords & Cables

Control Cable

Crane Cable

D

Diesel Locomotive Cable

Direct Burial Cable

Drop Cable

E

Elevator Cables

Extension Cords

Entertainment Cable

F

Festoon Cable

Flexible Cord

Flexible Power Cable

G

G, & G-GC Cable

Ground Wire

H

Hospital Cable

I

Industrial Control Cable

Instrumentation Cable

L

Lamp Cord

Laser Control Cable

Lighting Cable (Stage)

Locomotive Cable

M

Marine Cable

Medical Cable

Microphone Cable

Mil Spec 3432

Mining Cable

Motor Lead Wire

Movie Industry Cable

Multi-Conductors

Music Instrument

N

Navy Cable

O

Oil Industry Cable

Overhead Cable

P

Parallel Power Cable

PPE Cable

Portable Power Cable

R

Rail Road Cable

Robotic Control Cable

S

SEOWA, SJEOWA

SVEO

Stage Lighting Cable

Submersible Pump Cable

T

Trailer Cable

W

W Cable

Welding Cable

BRONCO-125™ Test Report

+125°C TO -65°C

Thermoplastic Vulcanizate (TPV) Advanced Synthetic Rubber

BRONCO-125™ Provides Superior:

- Oil Resistance

- High/Low Temperature

- Heat Aging

- Ozone Resistance

- Chemical Resistance

- Abrasion Resistance

- Mechanical Strength

- Lighter Weight

LOWER TEMPERATURE FLEXIBILITY

BRONCO-125™ rubber flexible cord jackets resist cracking

to lower temperatures than either thermoset Neoprene or

thermoset rubber. The following are results of bend tests:

|

BRONCO-125™

Type SEO |

RUBBER

Type S |

NEOPRENE

Type SO |

| Cold Bend @ -35°C |

Pass |

Pass |

Pass |

| Cold Bend @ -50°C |

Pass |

Cracked |

Cracked |

| Cold Bend @ -65°C |

Pass |

Cracked |

Cracked |

PHILAFIN™ cables & cords are UL rated at -50°C to +105°E.

GREATER OZONE RESISTANCE

Ozone as generated around most electrical equipment can

cause cracking in most conventional rubbers. BRONCO-

125™ rubber has excellent resistance to cracking caused by

ozone. Below are results of bent loop ozone aging tests of

flexible cord jackets.

|

BRONCO-125™

Type SEO |

RUBBER

Type S |

NEOPRENE

Type SO |

| Hours to Cracking |

1,000 |

24 |

300 |

NOTE: OZONE EXPOSURE - 100pphm/100°F

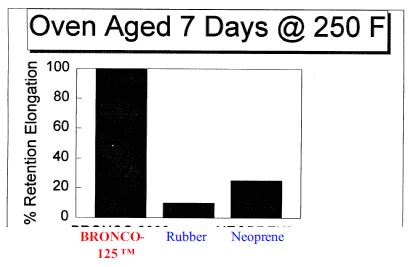

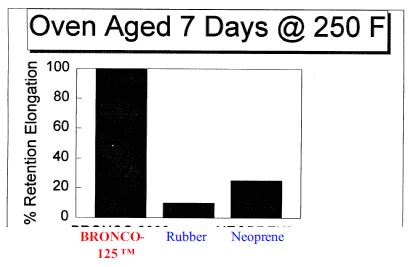

SUPERIOR HEAT AGING

BRONCO-125™ rubber resists cracking and brittleness

caused by heat far better than Neoprene or rubber.

Comparative heat aging at 250EF. is shown

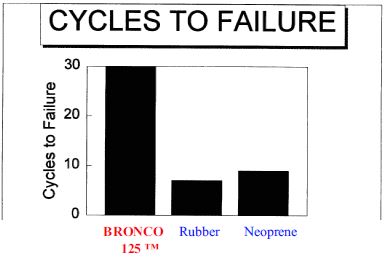

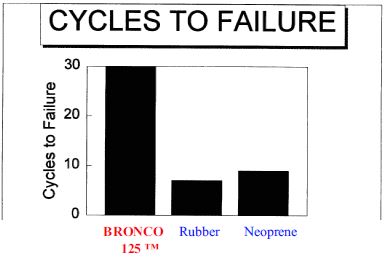

TOUGHER ABRASION RESISTANCE

Shown below are comparative grinding wheel type abrasion

test results on flexible cord jackets. Again, BRONCO-125™

rubber outperforms Neoprene and rubber flexible cordjackets.

SUPERIOR MECHANICAL STRENGTH

One measure of the mechanical strength of a flexible cord is

resistance to failure under a crushing load. Below are results of

crushing strength tests for flexible cords.

CRUSHING STRENGTH

|

BRONCO-125™

Type SEO |

RUBBER

Type S |

NEOPRENE

Type SO |

Pounds Force

@ Failure |

3,400 |

2,000 |

3,000 |

LIGHTER WEIGHT

Another important consideration in "portable" power supply

cordage is weight. PHILAFIN can offer a lighter, more portable

cable than either rubber or Neoprene. Typical weight savings on

12/3 cords are shown as follows:

12/3 CORDAGE WEIGHT

|

BRONCO-125™

Type SEO |

RUBBER

Type S |

NEOPRENE

Type SO |

| Pounds Per 1000 FT. |

164 |

199 |

235 |

| Weight Reduction |

n/a |

18% |

33% |

COMPARISON OF FLEXIBLE CORD JACKET MATERIALS

UNAGED PHYSICALS

|

BRONCO-125™

Type SEO |

RUBBER

Type S |

NEOPRENE

Type SO |

| Tensile Strength (PSI) |

2,000 |

1,420 |

1,630 |

| 100% Modulus (PSI) |

340 |

690 |

770 |

| Elongation (%) |

550 |

300 |

300 |

LOW TEMPERATURE PROPERTIES

|

BRONCO-125™

Type SEO |

RUBBER

Type S |

NEOPRENE

Type SO |

| Brittle Point (°F) |

-100° |

-52° |

-38° |

| Cold bend @-35°C |

Pass |

Pass |

Pass |

| Cold bend @-50°C |

Pass |

Failed |

Failed |

| Cold bend @-65°C |

Pass |

Failed |

Failed |

AGING PROPERTIES

|

BRONCO-125™

Type SEO |

RUBBER

Type S |

NEOPRENE

Type SO |

| Air Oven 7 Days @ 121°C |

| % Retention of Tensile |

123 |

104 |

188 |

| % Retention of Elongation |

89 |

17 |

17 |

| Air Oven 7 Days @ 136°C |

| % Retention of Tensile |

150 |

0 |

0 |

| % Retention of Elongation |

116 |

0 |

0 |

| Air Bomb 43 Hrs.@ 127°C |

| % Retention of Tensile |

117 |

56 |

93 |

| % Retention of Elongation |

116 |

18 |

43 |

OZONE RESISTANCE

|

BRONCO-125™

Type SEO |

RUBBER

Type S |

NEOPRENE

Type SO |

| Hours To Cracking (100 pphm/100°F) |

1000 |

24 |

300 |

HEAT DEFORMATION (T2/T1)

|

BRONCO-125™

Type SEO |

RUBBER

Type S |

NEOPRENE

Type SO |

| 2000 gms @ 121°C |

.76 |

.93 |

.95 |

MECHANICAL PROPERTIES

|

BRONCO-125™

Type SEO |

RUBBER

Type S |

NEOPRENE

Type SO |

| (Crushing Strength) Lbs. Force To Failure |

3,400 |

2,000 |

3,000 |

| Abrasion Resistance Cycles To Wear Through Jacket |

36 |

18 |

14 |

CHEMICAL RESISTANCE

% Diameter Change--30 Day Immersion at Room Temperature

|

BRONCO-125™

Type SEO |

RUBBER

Type S |

NEOPRENE

Type SO |

| Alcohol--Ethyl |

0 |

-1 |

0 |

| Ammonia |

1 |

2 |

1 |

| Gasoline--Unleaded |

61 |

58 |

63 |

| Kerosene |

34 |

25 |

17 |

| Oil--Motor 10/40 |

9 |

6 |

0 |

| Oil--Vegetable |

-2 |

6 |

0 |

| Skydrol 500 |

0 |

-3 |

22 |

| Toluene |

26 |

60 |

56 |

| Water |

-1 |

-2 |

-1 |